|

||||||

[ Home ]

|

Tool DressersTool Dressers worked hard over hot fire to heat up bit. The temperature had to be hot enough to shape the bit but not hot enough to burn the steel. “Sharpening” a bit meant two men hitting it with 14lb or 16 lb sledgehammers and shaping the tip. This needed to be precision work. Each hit had to be in the same spot. If the end was heat the bit would have to be reshaped. Each bit had to be properly tempered-too soft and the end could flatten, too hard and it could chip. Different types of rock would wear the edge of the bit but the tool dresser had to maintain a sharp bit of the proper size. A very strenuous job but a necessary one to keep bits in good condition for continued drilling.

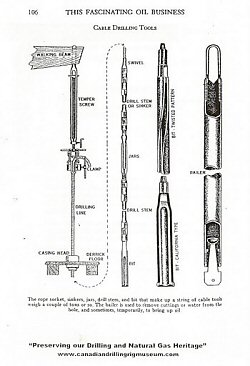

Diagram of cable drilling tools. Jack Culver oversees as Bob Elfner and Jerry McKenzie sharpen a drill bit. The following is a list in recognition of the dedicated tool dressers in the Haldimand area:

|